ATEQ is Available to Provide Consulting and Leak Testers For Fuel Cell EV Bipolar Plate Leak Testing Applications.

Fuel cells are the current focus of research for fuel cell vehicle applications. The membrane electrode assembly in a polymer electrolyte membrane fuel cell is where the power is produced and consists of a membrane, catalyst layers and gas diffusion layers. These layers are stacked on top of each other to provide a usable output voltage. Learn more about the parts of a fuel cell at energy.gov.

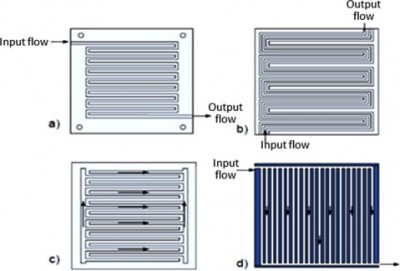

Each cell in the fuel cell stack is sandwiched between two bipolar plates to separate it from neighboring cells. Bipolar plates provide electrical conduction between the cells and can be made of metal, carbon, or composites. A “flow field,” set of channels is stamped into the plate’s surface to allow gases to flow over the fuel cell. Additional channels inside each plate may be used to circulate a liquid coolant. Learn more about bipolar plates at sciencedirect.com.

The flow fields in the bipolar plates need to be flow tested to make sure a safe specified amount of gas is flowing over the fuel cell and leak tested to make sure the liquid coolant in the channels doesn’t leak. Leak testing bipolar plates can be tricky due to their flexible nature of the material used and all of the flow channels in the plate.

ATEQ has experience flow testing bipolar plates and can work with you on a custom solution for your bipolar leak testing application.

Contact Us to speak with an expert ATEQ Application Engineer in your area.