PRIMUS F620

VERSATILE AIR LEAK DETECTOR

The ATEQ® Primus F620 is the state of the art color screen compact air leak detector designed to test the air-tightness of parts on production lines. It is specially adapted for automatic and semi-automatic workbenches. The method used is based on the measurement of a small variation or drop in differential pressure between the test and reference parts, when both are filled to an identical pressure. This versatile instrument can be used for indirect tests, sealed component testing and high speed testing of components with small volumes with the optional “mini-valve”.

PRIMUS F620 : APPLICATIONS

Automotive, domestic appliances, medical, aeronautic, defense, fluid and electrical components, food and cosmetic packaging…

ATEQ’s Primus air leak tester equipment comes with a couple of different options. We carry a smaller, more compact model designed for direct and indirect testing of flow and continuous flow measurements. Our larger model is designed for differential pressure decay, which measures in pressure and vacuum readings. Both models provide extremely accurate results and have high durability. Both of our air leak detectors come equipped with color display screens. With these models, you can cover a wide range of applications.

With over 40 years of experience in air flow and leak detection technology, ATEQ’s your only option. Call one of our team members today to learn more about our Primus air leak testing equipment.

PRIMUS F620 : FEATURES

• Differential pressure decay leak measurement for use in pressure and vacuum.

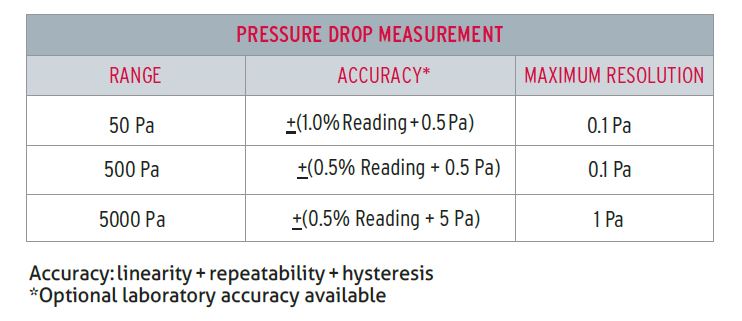

• Large range of leak measurement (∆P) F.S.: 50 Pa, 500 Pa or 5000 Pa

• 128 programs

• 2 languages (English + other one)

• Manual calibration on front panel with calibrated leak

TEST MODES :

• ∆P (Pa, 1/10 Pa)

• ∆P/t (Pa/s, 1/10 Pa/s)

• Flow units (sccm, mm3/s, cm3/s, cm3/min, cm3/h…)

• Blockage test

• and others, depending on your applications

ENVIRONMENT :

ROHS standard

FLEXIBLE COMMUNICATION FORMAT :

• RS232: printer

• Slave USB: supervision

• Master USB: USB key to transfer (parameters, results, statistics…)

• Option Fieldbus: Profibus, Devicenet, Profinet, Ethernet/IP

• Additional Master USB (option) on back panel (Bar code reader – remote control)

• Memory card for archiving results (1 Million)

MEASUREMENT CHARACTERISTICS :

ATEQ “Mini-Valve”

The ATEQ® “Mini-Valve” is an optional high-speed valve optimal for quickly testing components with small volumes.

In the pressure decay world, volume is the big enemy. The more volume is filled, the longer it takes to get into the test pressure, to stabilize and to test the part.

For small parts (up to 5cc) the absurd situation is that most of the volume tested is in the pipes and internal pneumatics of the instrument.

A standard ATEQ® valve is already twice as small as the nearest competitor. But ATEQ® has gone further with its mini-valve that has allowed it to achieve total cycle time (fill, stabilize, test, dump) down to 0.2 sec for leak rates as low as 0.5 cc/min.

Temperature Compensation

This is the crown jewel technology of ATEQ®. Not only does it compensate for temperature variations, but it learns from the results it gets and adapts itself to those results in a smart way.

Ballistic Full Feature & Electronic Regulator

Again, this feature is an ATEQ® exclusivity. In some applications, filling the part takes more than 1/3 of the total cycle time. ATEQ® has this innovative feature that will let the electronic pressure regulator open fully for a small amount of time, so the part fills up faster. The “Ballistic fill” does not only fill faster. It also helps to stabilize the part’s volume faster.

High Pressure

ATEQ® Primus can leak test components up to 80 bars (1250 PSI) in differential pressure mode. That remains unmatched in the industry.

Sealed Part Testing

Is your component sealed?

The Primus F620’s “Sealed component” can test components that do not have any openings to test.

What is so special about sealed components?

With pressure decay leak testers, the problem isn’t so much to find a small leak in a sealed part, but rather to detect a gross one. If the component has a big leak, then the internals will get filled at the fill stage, leaving no pressure to drop once the instrument gets into the test stage. ATEQ® has invented and patented the sealed component technic by performing a volume test prior to leak testing your part. So if there is a gross leak, the volume will be higher than expected and the test will fail.

PRIMUS F620 : SPECIFICATIONS

- PHYSICAL

- Weight : 7 Kg

- Dimensions : (WxHxD) 250x150x360 mm

- ELECTRICAL SUPPLY

- 24VDC/2A or 100-240VAC/50W

- TEMPERATURE

- Operating : + 5°C at + 45°C

- Storage : 0°C at + 60°C

INTERFACE

- Graphic color screen with simple and intuitive menu-driven operator controls

- SMART KEY : programmable key with user’s functions

- AIR SUPPLY

- Command 4/6 bar

- Pressure 1 or 2 bar > test pressure

- Clean and dry air

- Air quality standard to be applied (ISO 8573-1)

- Command 4/6 bar

PRIMUS F620 : OPTIONS

• 9 inputs / 5 local outputs compatible with 5 series instruments

• 6 inputs/ 6 outputs 24 V programmable for external automation

• Electronic regulator

• Dual pressure

• Automatic calibration check

• 2 pneumatic outputs for control of sealing connectors

• Memory card for archiving results (1 million)

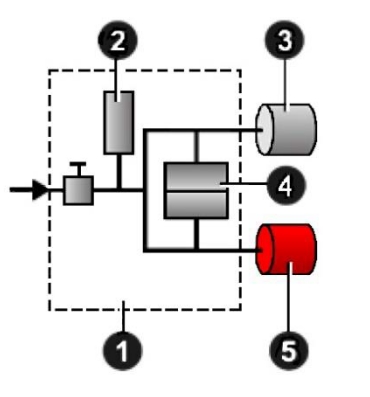

PRIMUS F620 : TECHNOLOGY

By far the most popular technology, differential pressure decay uses a reference volume to test your part. This helps compensate for any ambient pressure or temperature variations as they occur on both parts simultaneously.

Only a leak on the test part will result in a movement of our transducer’s membrane.

The second advantage of this method is that the accuracy does not drop with the test pressure as the transducer is measuring pressure differences between the two circuits, as opposed to the traditional pressure decay technology that measures pressure drops against the atmosphere.

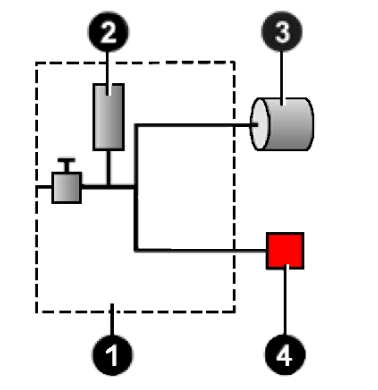

Direct measurement principle

The part under test 3 and the reference part 5 are filled to an identical pressure. A differential sensor 4 measures the pressure variation between the part under test 3 and the reference part 5. In some applications, the reference part can be replaced by a cap.

Desensitized test

This mode is used for the measurement of large leaks, when the reject level required is above the full scale of the differential sensor.

The test pressure is applied to the input of the part under test 3. The measurement is performed by the pressure sensor 2.

Other type of tests are available in option

PRIMUS F620 : FACTSHEETS

Detailed information about the PRIMUS F620 including features, specifications, etc.