The ATEQ electrical leak test is designed to detect defects in non-electrically conductive materials by utilizing high-voltage ionization and corona discharge principles. This process is effective in identifying small holes, thin material layers, and other imperfections in the test object. The method combines high voltage, sharp electrodes, and optionally vacuum or UV light, to enhance the precision of the leak detection process.

Step-by-Step Summary

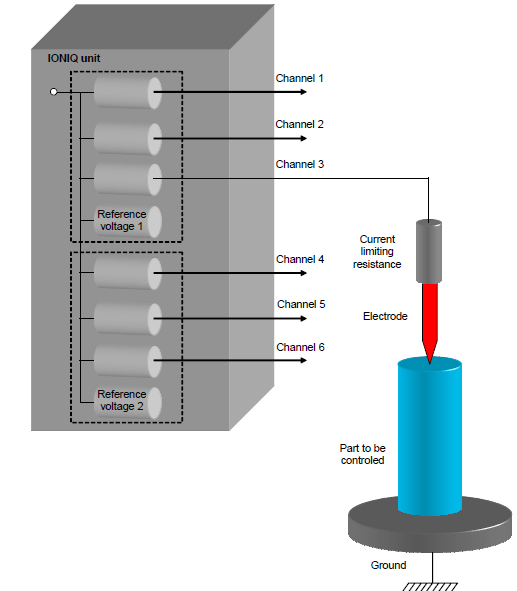

- Preparation of the Test Object: Place the object to be tested between the high-voltage electrode and a grounded electrode.

- Ionization and Corona Discharge: Use a high-voltage sharp electrode to ionize air molecules near the test surface. A vacuum or UV light can be used to optimize the ionization process.

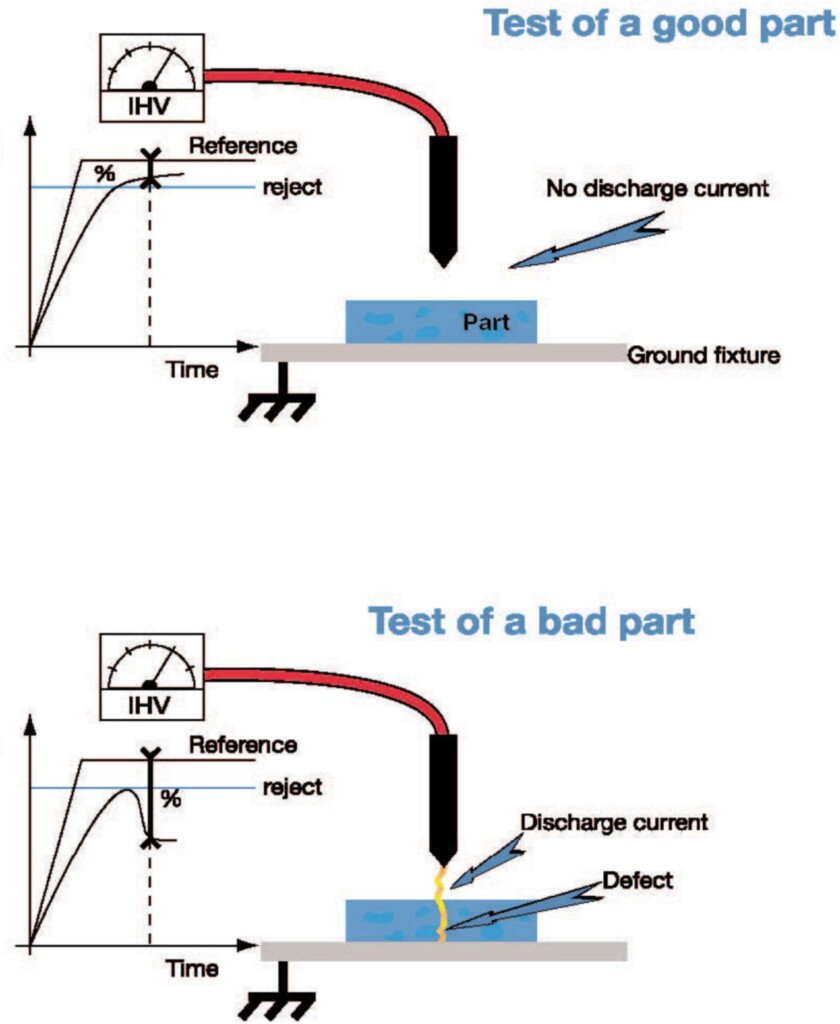

- Leak Detection: If the object has no leaks, the surface voltage will build up until it reaches the breakdown voltage. If there is a leak, ionized air allows corona conduction through the defect, resulting in a drop in voltage due to leakage current.

- Measurement and Analysis: The system measures the voltage drop or current flow through the defect. Precise detection is achieved by comparing the measured values to reference thresholds.

- Final Validation: Based on the results, determine whether the object passes or fails the test based on the presence and size of leaks.