FEATURES

GENERAL

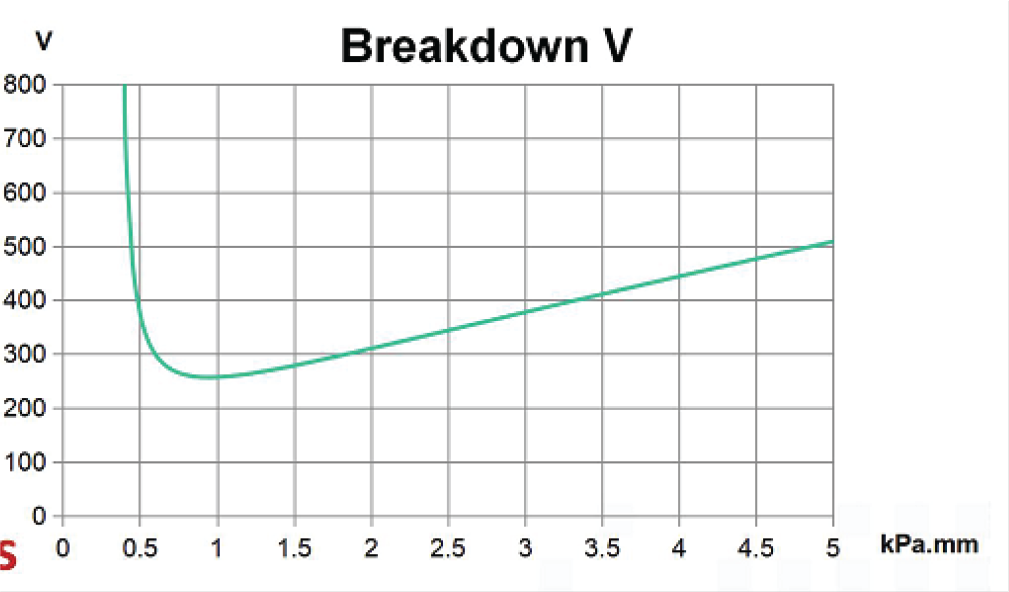

- Leak measurement using air ionization method

- Compact size

- Ethernet network up to 50 modules (Modbus IP)

- DIN rail mounting

ENVIRONMENT

- ROHS Standard

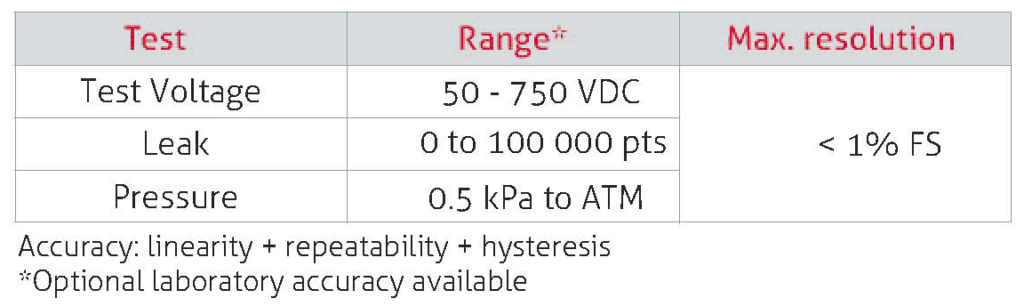

SPECIFICATIONS

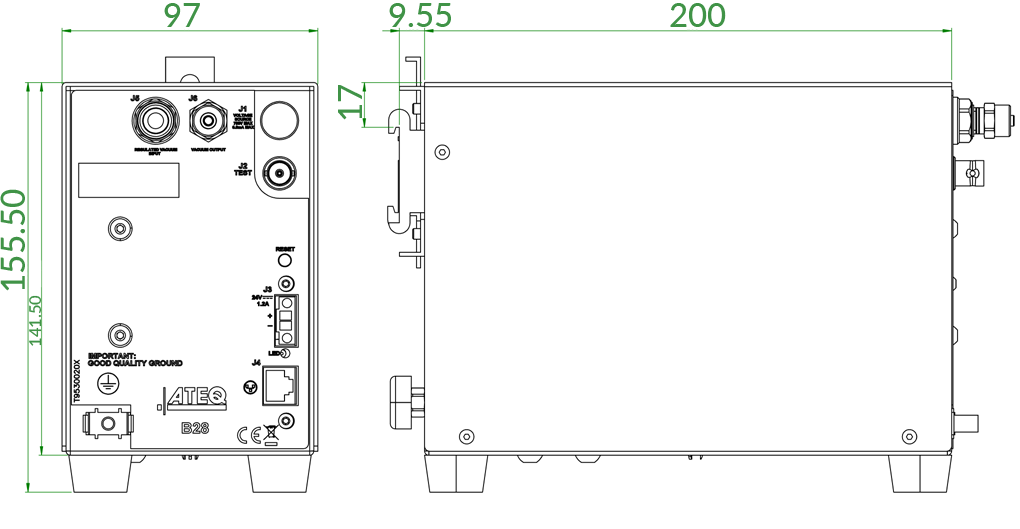

PHYSICAL

- Weight : approx.3.5 Kg

- Dimensions : (overall (mm): H 155.5 x L 97 x D 229.5

- TEMPERATURE

- Operating : + 5°C to + 45°C

- Storage : 0°C to + 60°C

EXTERNAL ELECTRICAL SUPPLY

- Voltage : 24 V DC / 1.6 A

- Main adaptater (included): 110 – 230 V AC

- Voltage : 24 V DC / 1.6 A