APPLICATION

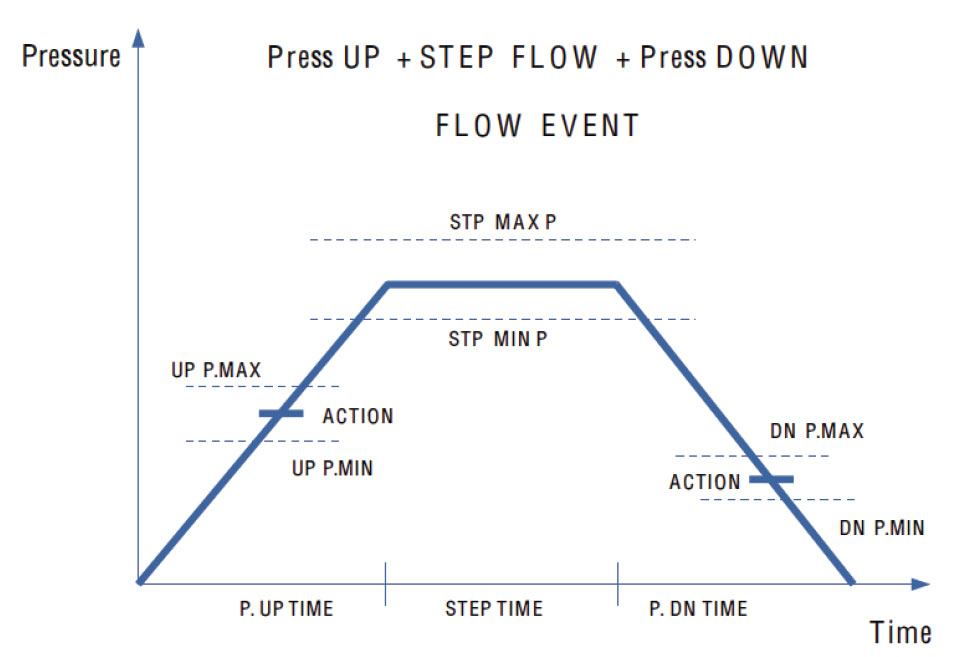

FLOW CONTROL

- Valves

- Opening valves

- Closing valves

FEATURES

GENERAL

- Flow measurement in direct or indirect testing

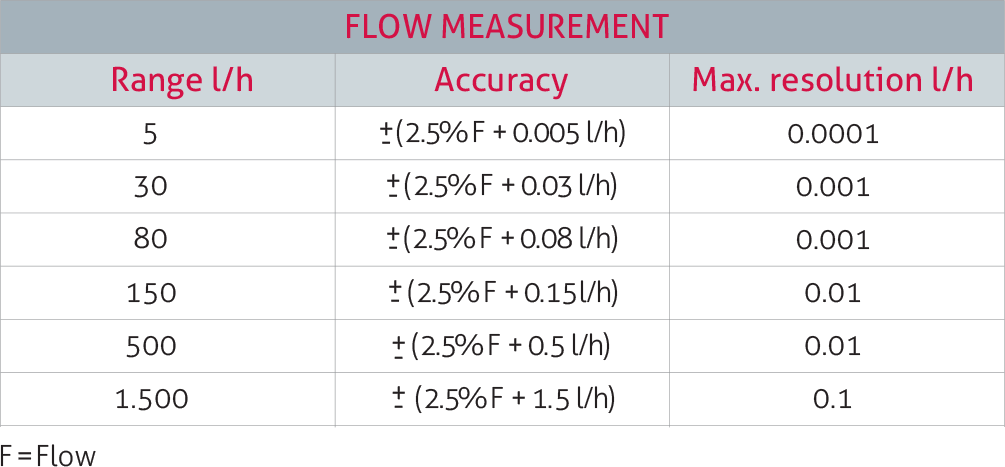

- Wide flow measurement range

- Setting on line (via USB)

- 2 languages (English + another one)

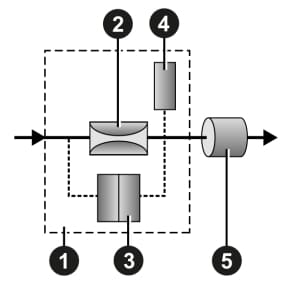

- Measurement element fully integrated into one module

- Data storage on internal memory or USB key

TEST MODES

- Flow units (sccm, mm³/s, cm³/s, cm³/min, cm³/h…)

ENVIRONMENT

- ROHS Standard

FLEXIBLE COMMUNICATION FORMAT

- RS232: Printer, Modbus RTU

- Slave USB: USB key ti transfer data (parameters, results…)

- Master USB: USB key to transfer (parameters, results, …)

- Option Fieldbus: Profibus, Devicenet, Profinet, Ethernet/IP

SPECIFICATIONS

- PHYSICAL

- Weight: 7 Kg

- Dimensions: (WxHxD) 250x150x360 mm

- ELECTRICAL SUPPLY

- 24VDC/2A or 100-240VAC/50W

- TEMPERATURE

- Operating: + 5°C at + 45°C

- Storage: 0°C at + 60°C

- INTERFACE

- Graphic color screen with simple and intuitive menu-driven operator controls

- SMART KEY: programmable key with user’s functions

- AIR SUPPLY

- Clean and dry air

- Air quality standard to be applied (ISO 8573-1)

- Clean and dry air

OPTIONS

ADD-ONS

- 9 inputs / 5 local outputs compatible with 5 series instruments

- 6 inputs/ 6 outputs 24 V programmable for external automation

- External capillary: Close to the test part

- 2 pneumatic outputs for control of sealing connectors

- Memory card for archiving results (400,000)

TECHNOLOGY

DOCUMENTATION