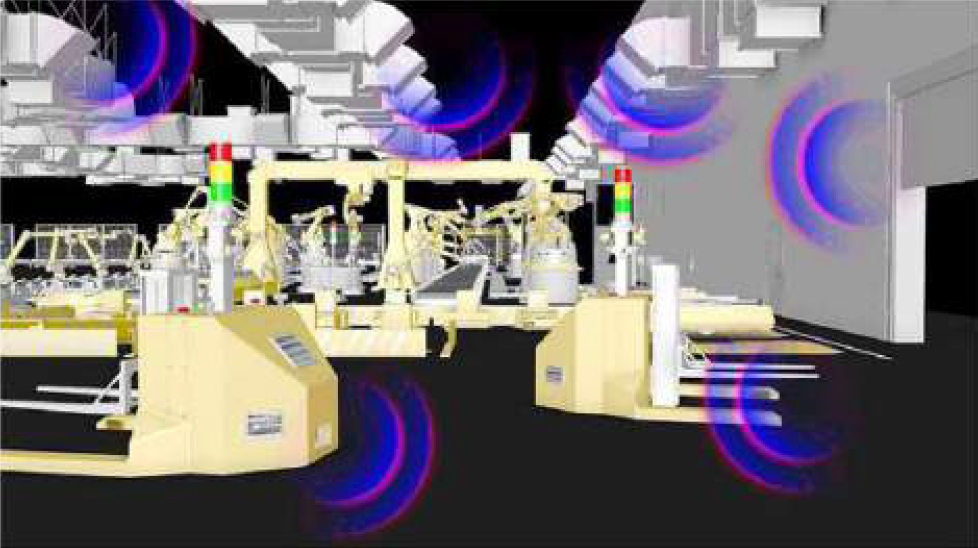

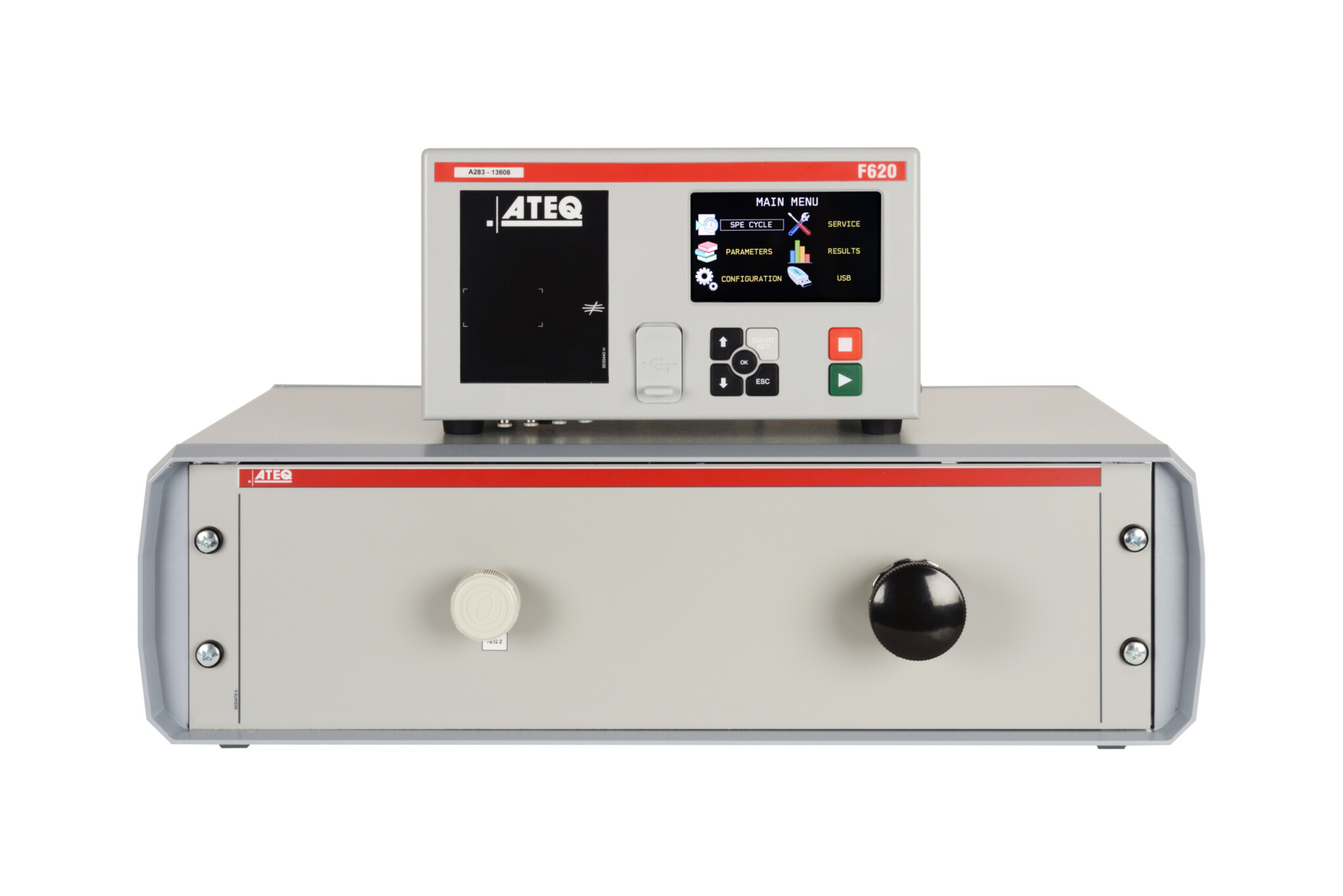

APPLICATION

EMOBILITY

AUTOMOTIVE

- Air Conditioning

- Radiators

- Exhaust

- Transmission…

FEATURES

GENERAL

- 128 programs

- Large Flow Valves for Quick Management of the Parts

- Fully Integrated Electronics and Pneumatics

ENVIRONMENT

- ROHS Standard

FLEXIBLE COMMUNICATION FORMAT

- RS232: Printer, Modbus RTU

- Slave USB: USB key ti transfer data (parameters, results…)

- Master USB: USB key to transfer (parameters, results, …)

- Option Fieldbus: Profibus, Devicenet, Profinet, Ethernet/IP

| MEASUREMENT CHARACTERISTICS |

|---|

| Range | Accuracy up to* | Max. Resolution |

|---|---|---|

| 0 – 20 Pa | > 2 Pa: 0.04 Pa

< 2 Pa: 2% Rdg |

0.001 Pa |

Accuracy: Linearity + Repeatability + Hysteresis *Optional Laboratory Accuracy **Maximum Test Pressure 3 bar

SPECIFICATIONS

- PHYSICAL

- Weight: 35 Kg

- Dimensions: (WxHxD) 500x550x260 mm

- ELECTRICAL SUPPLY

- 24 V DC / 1.6 A

- TEMPERATURE

- Operating: + 5°C at + 45°C

- Storage: 0°C at + 60°C

- AIR SUPPLY

- Clean and Dry Air

- Air Quality Standard to Be Applied (ISO 8573-1)

- Test Pressure Input, Needing an External Regulator

OPTIONS

ADD-ONS

- 9 inputs / 5 local outputs

- Optional Fieldbus: PROFIBUS, DeviceNet, PROFINET, Ethernet/IP, EtherCAT Network, Modbus RTU

- Early Decision Tool for Quick Defect Identification

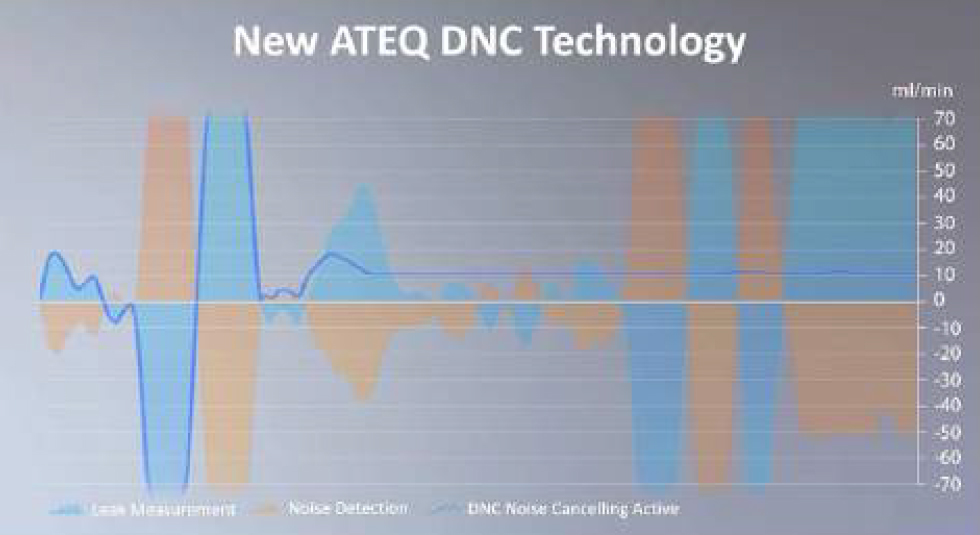

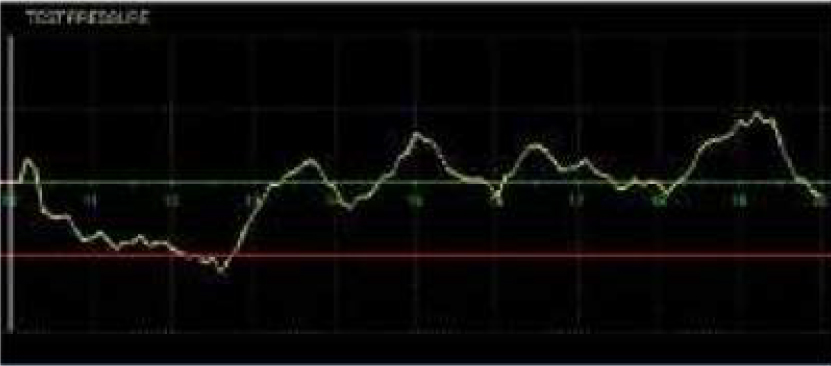

TECHNOLOGY

DOCUMENTATION