PERFORMANCE

Base unit performs evacuation (25″ Hg), vacuum decay test and tracer gas backfill to 700psig. Units can be configured to perform evacuation to lower vacuum levels.

FEATURES

GENERAL

- Recipes to include up to 10 leak locations, with user configurable dwell at each site

- Serial printer output

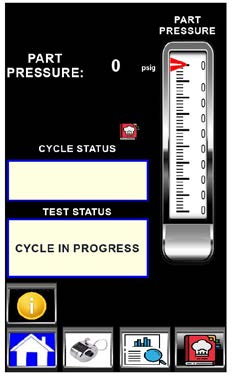

- Graphical user interface witch color touch screen

- Password protection prevents unauthorized access

- Built-in gross leak test eliminates tracer gas saturation

STANDARD CAPABILITIES

- Maximum fill, pressures are up to 700psig

- Ability to store up to 50-part recipes

- Touch screen 7″ color (HMI) for full system configuration/diagnostics display

- 16-bit analog input resolution on the pressure transducer

- System includes all necessary controls, gauging & valving

- 3CFM oilless product evacuation pump

- Data storage and retrieval from front mounted USB port

FLEXIBLE COMMUNICATION FORMAT

- Data logging over Ethernet

- Allen Bradley MicroLogix 1400 PLC for all control, set-points

- Fully integrable with our tracer gas sniffers

SPECIFICATIONS

- PHYSICAL

- Dimensions: (WxHxD) 344 x 395 x 618 mm

- Dimensions: (WxHxD) 344 x 395 x 618 mm

- ELECTRICAL SUPPLY

- Universal Voltage 110 vac or 220-Volt AC, 50 – 60 Hz, 6.5 amps nominal

- UTILITY FITTINGS

- 1⁄4” NPT female

- 1⁄2” NPT female for Part Evacuation

- PRESSURE TRANSDUCER

- Resolution of 0.01 psi in vacuum mode, or in pressure mode. Accuracy of ± 0.25%.

- Resolution of 0.01 psi in vacuum mode, or in pressure mode. Accuracy of ± 0.25%.

- VALVING

-

Fast acting pull type solenoid featuring epoxy encapsulated design

-

- MANIFOLDING

-

Seamless tubing with compression fitting interconnects. Helium leak tested to 1.0 × 10-6 atm-cc/sec@700 psig

-

- PRODUCT EVACUATION PUMP

- Air Driven Venturi Pump Providing ultimate vacuum level 25.5″ Hg

- ELECTRONICS

- Microprocessor-based programmable logic controller

- GAUGING

- Digital part pressure and leak rate displayed on operator interface

OPTIONS

ADD-ONS

- Analog

- User I/O

- Printer

- Low Pressure Feature, 0-20psig

- Nitrogen Charge up to 700psig

- Barcode Scanner Feature

DOCUMENTATION