EV LEAK TESTING

EV LEAK TESTING SPECIALISTS

Electric Mobility Leak Detection That Fit Your Needs

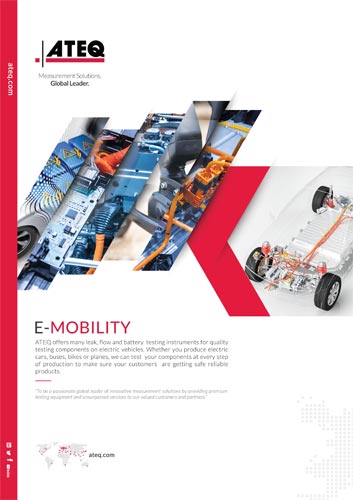

The eMobility sector, including electric vehicles, e-bikes, electric scooters, and other electrically powered solutions, is rapidly shaping the future of transportation. As this industry blossoms, ensuring the reliability, safety, and efficiency of its products becomes paramount. At ATEQ, we are committed to partnering with our clients during this transition, offering tailored EV leak testing solutions to meet your specific needs.

Safety remains at the forefront of eMobility. Whether it’s the battery systems in an electric car, the electronic components in an e-bike, or the circuits in an electric scooter, each needs meticulous testing to guarantee optimal functioning. ATEQ’s state-of-the-art testing technologies cater to the diverse range of eMobility products, ensuring everything from battery trays to electronic systems are free from defects.

Short-Cycle EV Leak Testing for Your Production Line

Efficiency and longevity are pivotal for the broader acceptance of eMobility solutions. As consumers lean towards sustainable transportation, they ask for products that are not only environmentally friendly but also reliable and long-lasting. By ensuring that components, regardless of their size or function, meet rigorous quality standards, ATEQ helps EV manufacturers deliver products that provide performance, durability, and customer satisfaction.

“The F620 is easy to operate and perfectly meets our needs.”