Introduction to Helium Leak Testing

Helium leak testing is an indispensable procedure that plays a critical role in various industries, from aerospace and automotive to medical devices and energy sectors. This comprehensive guide aims to be your one-stop resource for understanding helium leak testing. We’ll delve into its methods, why helium is the preferred gas for this type of testing, how to perform a helium leak test, its advantages, and its diverse applications. Whether you’re an engineer looking to improve your testing processes or a business owner aiming to ensure the highest quality and safety standards, this guide offers insights that can benefit a wide range of professionals. With the increasing demand for leak-proof systems in high-stakes environments, mastering helium leak testing has never been more important.

What is Helium Leak Testing?

Helium leak testing is a highly specialized, non-destructive testing method used to detect and locate leaks in a system or component. This method employs helium, an inert, non-toxic, and non-flammable gas, as a tracer to find leaks in even the most intricate systems. The sensitivity of this method is unparalleled, capable of detecting leaks as minuscule as 1×10^-12 mbar*l/s. This makes it the go-to method for applications where even the smallest leak could be catastrophic.

Why do we use Helium for a Leak Test?

1. High Sensitivity: The small molecular size of helium allows for the detection of extremely tiny leaks that other gases might not catch.

2. Inert Nature: Helium is chemically inert, meaning it won’t react with the materials being tested, ensuring that the test results are not compromised.

3. Non-Flammable: The non-flammable nature of helium makes it a safe choice, eliminating the risk of fire during testing.

4. Versatility: These machines are adaptable and can be used for a wide range of applications, from testing automotive parts to ensuring the integrity of spacecraft components.

5. Speed: Helium leak testing is often faster than many other testing methods, saving valuable time in production or maintenance schedules.

What are the Different Applications for Helium Leak Testing?

Aerospace: Ensuring the integrity of fuel systems, oxygen supply lines, and other critical components is paramount in aerospace applications.

Automotive: In the automotive industry, helium leak testing is used for testing fuel tanks, radiators, air-conditioning systems.

Medical Devices: Ensuring the sterility and integrity of medical implants, surgical instruments, and other devices is crucial, making helium leak testing an ideal choice.

Battery: In the energy industry, helium leak testing is used to test the integrity of the battery pack, battery housing, and even pouches and cells to prevent leaks and ensure safety.

Military: In military applications, helium leak testing is vital for ensuring the reliability of weapons systems, communication equipment, and vehicles. The method is used to detect leaks in everything from missile casings to submarine hulls, contributing to national security.

How Does a Helium Leak Detector Work?

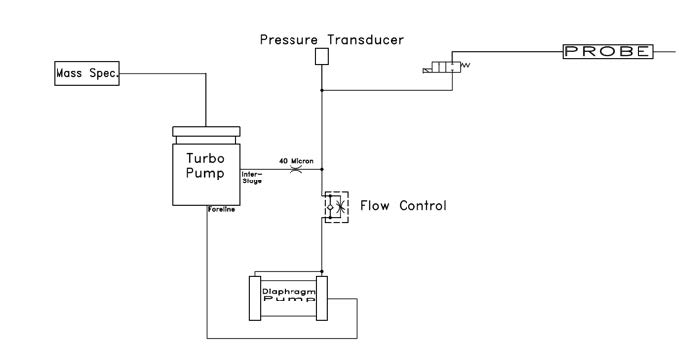

Helium leak detectors operate based on the principle of mass spectrometry. When a system is suspected of having a leak, it is evacuated and then filled with helium. Being one of the smallest and lightest molecules, helium has an innate ability to pass through even the tiniest of openings. The helium that escapes through these leaks is drawn into the leak detector, where it is ionized and passed through a magnetic field. This process separates the helium ions from other gases. A detector then measures the quantity of helium ions, allowing for precise identification and localization of leaks. Due to its efficiency and accuracy, helium leak detection is a preferred method for many industries to ensure the integrity of their systems.

The efficacy of helium as a tracer gas stems from its minimal presence in our atmosphere, at just 0.0005%. This ensures low interference during testing. When a system is filled with helium, any external detection indicates a leak. The rapid movement of helium molecules allows for quick detection. Modern helium leak detectors have vacuum pumps, enhancing sensitivity. They’re calibrated using leak standards for accuracy. With technological advancements, these detectors are now more compact and essential in industries like automotive and aerospace, where tiny leaks can be critical.

ATEQ INSTRUMENTS FOR HELIUM LEAK TESTING

Multiple Solutions For Leak Detection Application Requirements

At ATEQ, we designs and manufactures portable portable helium tracer gas leak detectors, console tracer gas leak detectors, helium and dual gas portable leak detectors with sniffing and fully integrated smart charge and back-fill station, integrated tracer gas leak detection systems, calibrated gas leaks, and accessories.

Custom Integrated Leak Detection Systems Engineering

Our base system technologies can be custom engineered to include integrated tooling/fixtures, automation and control, application-specific features, leak standard data collection requirements, and more. Please call us for custom engineering our systems, we have a customer-centric and application specific approach and integrated design project engineering to build systems that meet customers needs.

Leave A Comment

You must be logged in to post a comment.