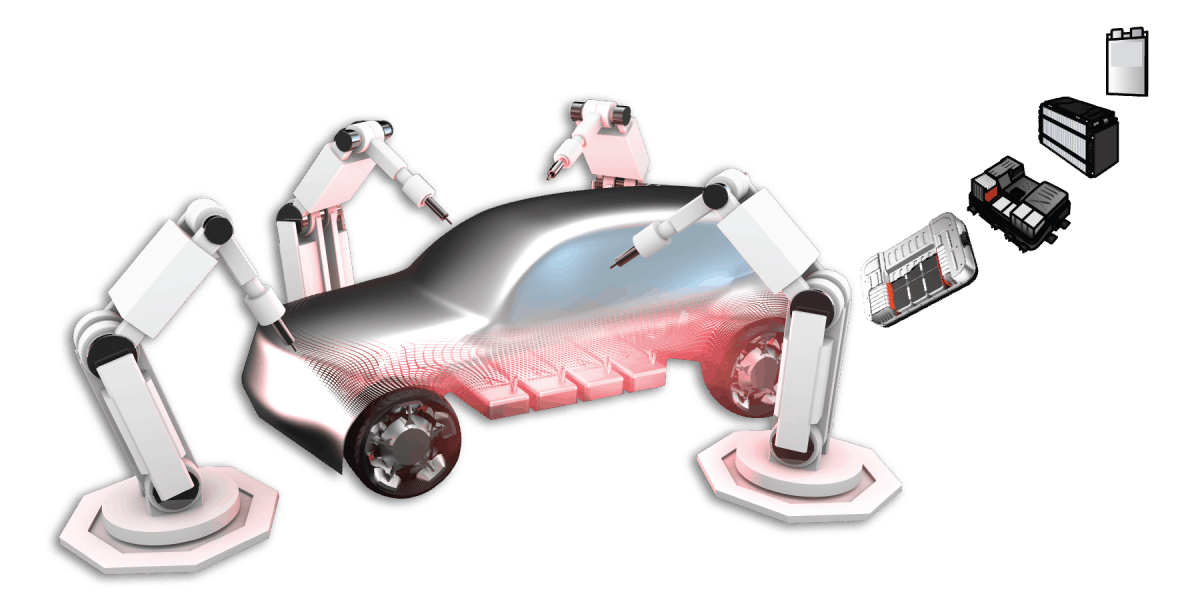

BATTERY LEAK TESTING

ATEQ has a variety of methods to leak test batteries throughout the production process. Leak testing electrical vehicle battery cells, for example, begins with an ionic leak test of the battery cell pouch and ends with pressure leak testing the entire battery tray.

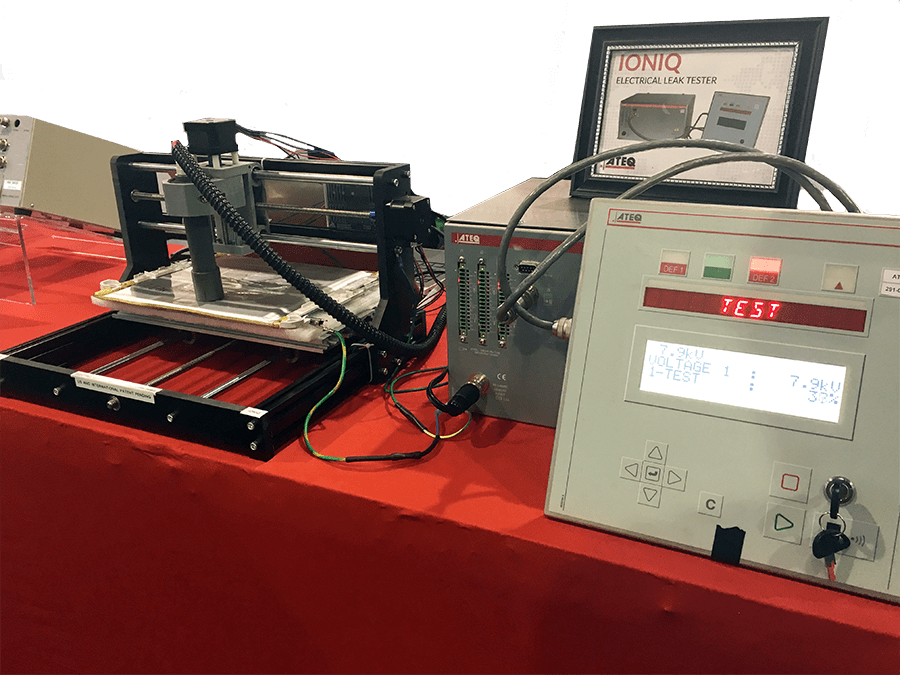

For battery leak testing of the cell, ATEQ presents the new patented B28 testing method which offers a safe low ionization voltage to ionize oxygen molecules in the air around the battery cell. If the battery cell is properly insulated, the instrument will show a 100% reading. If there is a leak in the battery insulation, ionized oxygen molecules will be able to flow through the hole and the ions will connect to the inside of the battery cell, without igniting it. This will show a 0% insulation percentage reading on the instrument and the operator or machine can then reject the part.

The B28 can be automated into a production line to support fast pass/fail testing of the cell. The faulty part could then be taken to a rework bench for manual leak localization testing by using the Ioniq wand to find where on the cell the testing needle creates a zero percent reading on the instrument.

After the battery cells pass the ionization leak test, the next phases are putting several cells together to create a battery module, combining the modules into a battery pack then putting several battery packs together into a battery tray. Each of these battery packages requires leak testing. Leak testing battery modules, packs or trays involves a different type of leak testing than the cells. ATEQ differential pressure decay leak testers, like the Primus F620, can test the battery packaging by sealing off the packaging openings and injecting the package with compressed air, measuring the pressure and measuring how much the pressure drops, which would signify a leaking battery pack. If the leak rate is within testing specifications, the battery packaging is airtight.

For more information about our range of battery leak testing products, see our Battery Brochure.

ATEQ also has a new Electric Vehicle Battery Module Balancer!

To talk to an expert about your battery applications, contact us!

“Ateq is dedicated to your long-term success”

Contact ATEQ USA for sales information, general questions, press release information and marketing inquiries.