Mass Flow Leak Testing: The Differential Method

What is a Mass Flow Leak Test?

Mass flow is a non-destructive method of leak testing used to ensure the air tightness of various parts or components on the production line. This type of leak testing is highly effective for detecting small leaks in parts of all sizes; however, mass flow leak testers are commonly used to efficiently test large-volume parts.

Mass flow testers are also typically used to test parts with multiple cavities of varying volumes, and parts that function by allowing gas, air, or fluid to flow through them. Mass flow tests are not only perfect for leak detection but occlusion and blockage testing as well.

The mass flow leak method is derived from the Poiseuille Law, an example is provided in the formula below:

Differential Mass Flow Testing

There are various forms and methods to perform mass flow leak testing. As differential mass flow leak testing is the most repeatable and accurate of these methods; This blog article will focus on the differential method.

With the differential mass flow leak test method, a reference volume is used that is designed to match the physical properties of the part under the test. The reference volume is used to balance adiabatic factors produced on the test side. When performing a mass leak test specifically ATEQ recommends that clients use the differential mass flow leak testing method for smaller flows up to 200 sccm. Especially, when critical leak testing and flow requirements must be met to ensure the end user’s safety.

How is a Differential Mass Flow Leak Test Performed?

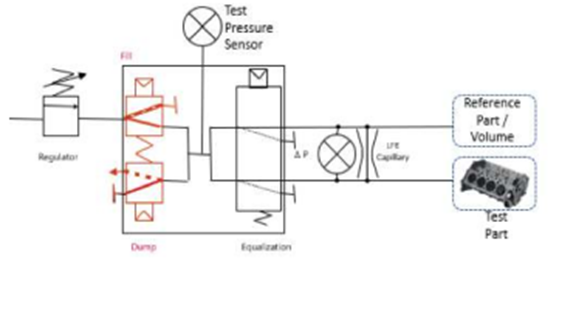

Step 1 Connect: The part that will undergo testing is connected to the leak tester’s test port, and the reference part/volume is connected to the reference port.

Note: In an ATEQ mass flow leak tester there will be two mass flow sensors; One will measure the test pressure and the second will measure the air going through the laminar flow capillary.

Step 2 Fill: During the fill stage, both parts are filled by regulated test air to the specified test pressure.

Step 3 Stabilization: The test and reference volume are isolated from the fill source and all adiabatic effects caused by pressurization are allowed to dissipate. The instrumentation will then monitor the pressure on both sides with the internal pressure sensor.

Step 4 During the Test: After stabilization of the test pressure the instrument will then perform a measurement using the custom ATEQ differential sensor. If there is a leak in the test part, air will pass from the non-leak reference, through the capillary, across the differential transducer, and out the leak path in the test part. If there is not a leak in the test part, there is no flow across the capillary and nothing for the differential to measure.

Step 5 Dump: After the test has been performed air can be exhausted internally through the instrument valve or an external valve can be used to prevent the instrument valve from becoming contaminated from moisture or particulates.

Advantages of a Differential Mass Flow Leak Test?

- Detection of small leaks with big volumes.

- Allows more stable test pressures of replacement air during testing.

- Leak readings are highly accurate over a wide range of leak volume ratios.

- Operator independent, integrated easily for automated and semi-automated leak testing.

- Ability to get repeatability with a direct measurement from the flow rate.

- High-speed cycle times due to the differential method

Differential Mass Flow Industries & Applications:

Differential mass flow leak testers have numerous application capabilities and can be used effectively in various industries. The differential mass flow principle can be applied to any application with cavities that have the potential to leak both internally and externally.

The industries that most commonly use differential mass flow leak testers are ICE and ZEV, automotive manufacturers. Differential Mass Flow instruments are used to measure the leak rate for applications such as Engine blocks, Transmission cases, torque converter housing, electric drive units, Housing end cases, Valves & tubing for H2 tanks just to name a few.

Differential Mass Flow Leak Equipment

Selecting the right instrument for your application is key when it comes to getting repeatable accurate results. ATEQ has several types of flow testers that can be customized for your specific application.

In addition to the aforementioned advantages there are several benefits to selecting an ATEQ differential mass flow leak tester.

- Factory Calibration eliminates the need to “Comp and Cal” by using zero as an absolute value.

- ATEQ-designed circuit allows manufacturers to find external leaks in products while a large internal leak exists between two cavities. This capability makes the instrumentation ideal for engine and transmission applications.

- ATEQ’s differential transducer is manufactured to have an extremely low delta P, allowing the instrumentation to find small leaks in large volumes.

An ATEQ expert engineer will assess your needs and develop a customized solution for your specific application requirements. Receive a complimentary consultation with a local engineer today!

Leave A Comment

You must be logged in to post a comment.