ATEQ is Available to Provide Consulting and Leak Testers and Flow Meters For Fuel Cell Leak Testing and Flow Testing Applications.

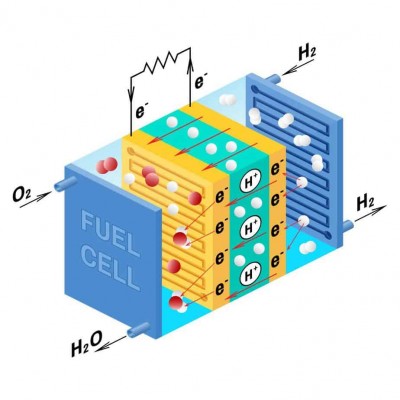

Fuel Cells are becoming popular in the e-mobility industry because fuel cell systems are a clean, efficient, reliable, and quiet source of power. A fuel cell creates electrochemical reactions between hydrogen and oxygen to generate electricity, heat and water. A fuel cell is composed of an anode, cathode, and an electrolyte membrane. Learn more about how fuel cells work at The Fuel Cell and Hydrogen Energy Association website.

The fuel side components are typically tested for leaks with a mix of 5% H2 (hydrogen) and 95% N2 (nitrogen) called forming gas. Contrary to pure hydrogen, forming gas is not flammable, and it helps detect defect areas that hydrogen could flow through. The air side is typically tested for leaks with an air pressure decay or mass flow instrument. The fuel cell’s semi-permeable membrane should be tested for air flow and the vehicle’s cooling system is leak tested with an air tester.

ATEQ has developed solutions for hundreds of different automotive leak testing applications for well known manufacturers over the last 40 years. Whether you are leak testing electric vehicles, batteries, smartphones, catheters, pacemakers, or a washing machine, ATEQ can work with you to provide efficient leak and flow testers and develop integrated fuel cell production leak and flow testing solutions.

Contact Us to speak with an expert ATEQ Application Engineer in your area.