AUTOMOTIVE LEAK TESTING

AUTOMOTIVE LEAK DETECTION

ATEQ’s Specialized Leak Testers for Automotive

ATEQ USA supplies advanced automotive leak detection and flow analysis equipment used by Tier 1 suppliers to ensure parts meet OEM specifications for component size, leak tolerance, and flow capacity. Testing is conducted with clean, dry air or bottled nitrogen. ATEQ also offers helium and hydrogen-based testers for high-sensitivity needs.

“ATEQ’s precise sensitivity allows manufacturers to quickly detect leaks beyond acceptable limits.“

OEMs use ATEQ testers to verify both individual components (e.g., hoses, valves, shock absorber, oil pan, AC systems, lights) and fully assembled systems, ensuring contract requirements are met. With ATEQ’s precise sensitivity, manufacturers can quickly detect leaks. Our solution includes sniffers for fast leak source identification, enabling technicians to resolve or replace faulty components.

Automotive Leak Detection Tailored to Your Needs

ATEQ’s automotive leak detection equipment is ideal for testing AC systems, ensuring refrigerant containment and preventing environmental damage. Leaks can also lead to costly repairs and system failures. OEMs rely on ATEQ to verify system performance before vehicles leave the plant, reducing liability and recall risks.

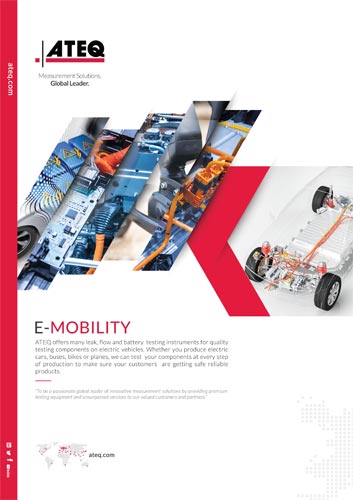

ATEQ also specializes in testing electric vehicle components like fuel cells, battery packs, hydrogen tanks, and more. Our expert sales team, with engineering backgrounds, can help identify the right testing solution for your needs. Contact us to meet your automotive leak testing goals.

“The F620 is easy to operate and perfectly meets our needs.”