G620 – COMPACT LEAK TESTER WITH CONTINUOUS FLOW

Without any doubt the smallest high-performance continuous flow tester on the market. Specially adapted for automatic or semi-automatic test machines, the G620 has a full range of specifications at a very competitive price. Continuous flow tester may help operators find leak locations and repair them.

G620 : APPLICATIONS

Automotive, small volume parts, injection rails, filter caps, gaz industry, cookers, gas float, heat exchangers for boilers, taps…

G620 : FEATURES

• Continuous flow leak detection

• 128 programs

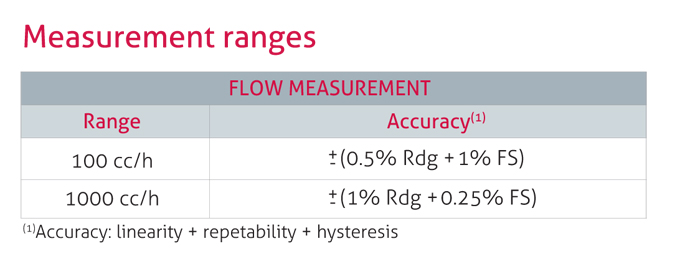

• 2 flow measurement ranges full scale : 100 or 1000 cm3.atm/h

• Measurement flow returned to standard conditions

• Calculation of the test part volume

• Setting on line (via USB)

• Automatic start

• 2 languages (English + other one)

• Manual calibration on front panel with calibrated leak

• Data storage on internal memory or USB key

ENVIRONMENT :

ROHS standard

FLEXIBLE COMMUNICATION FORMAT :

• RS232: printer, modbus RTU

• Slave USB: PC supervision (WinAteq 300, sesame)

• Master USB: USB key to transfert (parameters, results, …)

• Option Fieldbus: profibus, devicenet, profinet, Ethernet/IP

G620 : SPECIFICATIONS

- PHYSICAL

- Weight : 7 Kg / 14lbs

- Dimensions : (WxHxD) 250x150x360 mm

- ELECTRICAL SUPPLY

- 24 V DC / 1.6 A or 100 – 240 V AC / 50 W

- TEMPERATURE

- Operating : + 5°C at + 45°C

- Storage : 0°C at + 60°C

INTERFACE

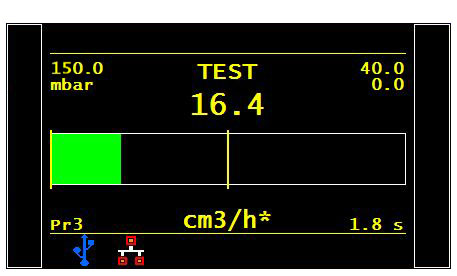

- Graphic color screen with simple and intuitive menu-driven operator controls

- SMART KEY : programmable key with user’s functions

- 4-line vacuum fluorescent display

- AIR SUPPLY

- Clean and dry air

- Air quality standard to be applied (ISO 8573-1)

- Clean and dry air

G620 : OPTIONS

• 7 inputs / 5 outputs

• 1 quick connectors for calibration checking

• 2 pneumatic outputs for control of sealing connectors

• 6 x 24 V programmable outputs for external connection

• 2 voltage Analogue Output

• Special valve (Shut off and or Bypass)

G620 : FACTSHEETS

Detailed information about the G620 including features, specifications, etc.

G620 : TECHNOLOGY

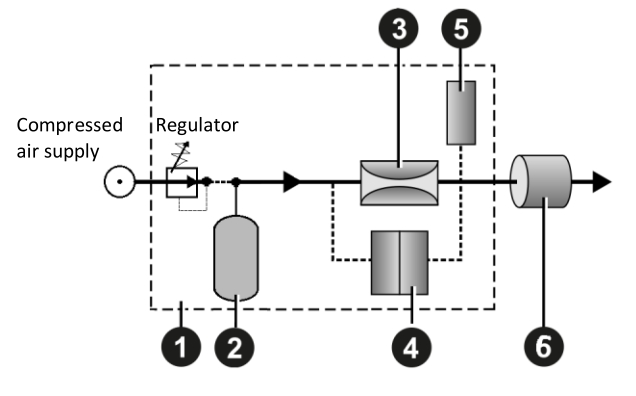

Often considered as a competitor to the Mass Flow technology, continuous flow relies on a differential pressure transducer and a very precise laminar flow tube to measure leak rates.

Its internal volume ensures that the flow generated by the leak remains very stable over time.

This technology is perfectly suited to the gas industry which sees it as a real time leak reader for gas appliances on production lines.

While the instrument generates a leak and shows its value on the screen, the operator can tighten the connections of the gas product until it reaches an acceptable leak rate.

When the part under test 6 is connected to the device 1, the internal tank 2 is pre-filled at the test pressure and then, it moves through a calibrated flow tube 3 which causes a drop in pressure. The pressure drop is measured by a differential pressure sensor 4. The pressure of the part under test 5 is measured by the sensor 5.

1 Device

2 Internal tank

3 Calibrated flow tube

4 Differential pressure sensor

5 Pressure sensor

6 Part under test