F28 LP

The F28 LP pressure decay or vaccum decay instrument is the latest addition to ATEQ’s new range : F28.

It’s a high performance, low cost, quality leak tester. Its small packaging enables mount it to near the test part ensuring the best measurement conditions. You can easily program and supervise it with our super friendly interface: F28 demo.

F28 LP: APPLICATIONS

PACKAGINGS

- Aerosol Caps

- Plastic Bags

- Sprays

- Plastic Bottles…

ELECTRONICS

- Hard Disk

- Watches

- TV Screen

- Camera Lenses…

MEDICAL

F28 LP: FEATURES

• Pressure decay leak measurement: vacuum to 20 bar

• Smart pressure regulation without regulator – auto fill (optional)

• Electronic regulation (optional)

• Units: Pa, Pa/s, sccm

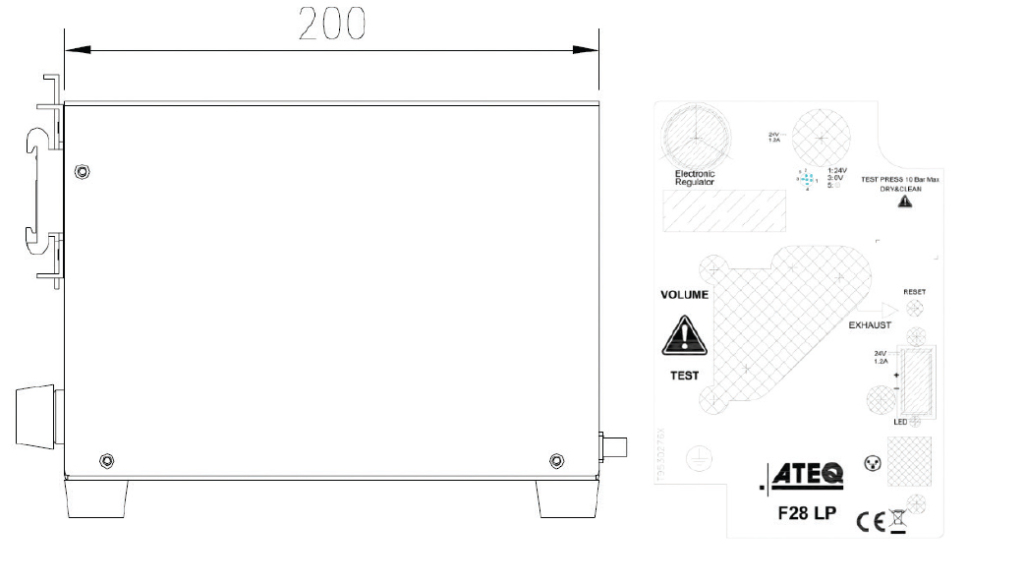

• Compact dimensions (overall (mm): h 141.5 x L 225 x D 97)

• Mechanical or electronic regulator from vacuum to 10 bar

• Integrated fill and dump valves

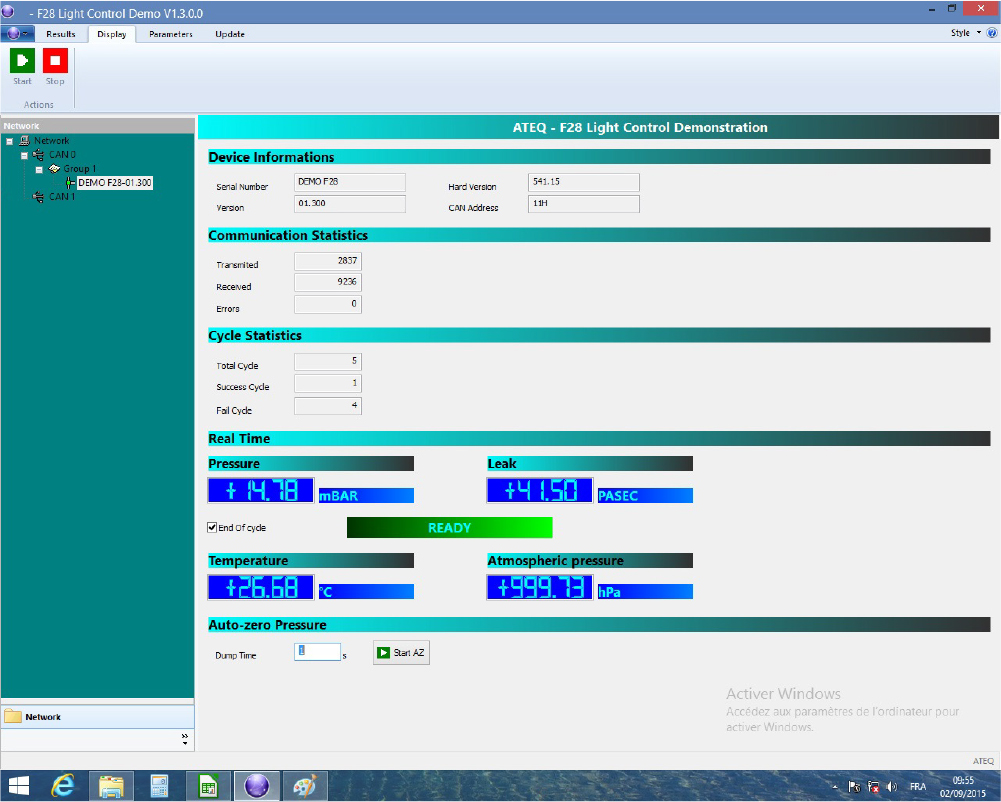

• Ethernet network up to 50 modules (Modbus IP)

• DIN rail mounting

• Environment: ROHS standard

| PRESSURE DROP MEASUREMENT |

|---|

| Full Scale | Vacuum | 500 mBar | 5 Bar | 10 Bar |

|---|---|---|---|---|

| 500 Pa | X | X | ||

| 1000 kPa | X | X | X | |

| 5.00 kPa | X | X | X | |

| 10.00 kPa | X | X | X | |

| 50.00 kPa | X | X | ||

| 100.00 kPa | X |

F28 LP Demo interface

F28 LP: TECHNOLOGY

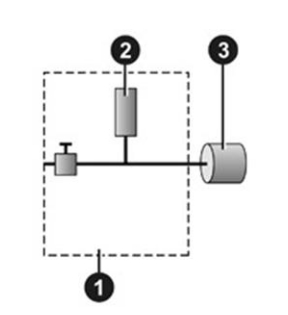

As a stripped down version of the previous technology, standard pressure decay compares the pressure on the part with the atmospheric pressure.

This technology is used when the application does not require a very high accuracy or a very fast cycle time. The method used is based on the measurement of a small variation or drop in pressure with a piezzo sensor.

Leak test and Desensitized Mode

The test pressure is applied to the input of the test part 3.

The measurement is performed by the pressure sensor 2.

1 Device

2 Pressure sensor

3 Part under test