APPLICATION

PACKAGINGS

- Aerosol Caps

- Plastic Bags

- Sprays

- Plastic Bottles...

ELECTRONICS

- Hard Disk

- Watches

- TV Screen

- Camera Lenses…

MEDICAL

FEATURES

GENERAL

- Pressure decay leak measurement: Vacuum

- Water leak detection by evaporation under strong vacuum

- Integrated fill and dump valves

- DIN rail mounting

TEST MODES

- Units: Pa, Pa/s, sccm, μg/min of H2O

ENVIRONMENT

- ROHS Standard

FLEXIBLE COMMUNICATION FORMAT

- Ethernet network up to 50 modules (Modbus IP)

| PRESSURE DROP MEASUREMENT |

|---|

| Range | Accuracy up to* | Max. Resolution | |

|---|---|---|---|

| Test Pressure (Absolute) | 0.05 to 110 kPa | 1 Pa | 2% FS |

| Vacuum Decay | 2000 kPa | 1 Pa | 2% FS |

Accuracy: Linearity + Repeatability + Hysteresis *Optional Laboratory Accuracy

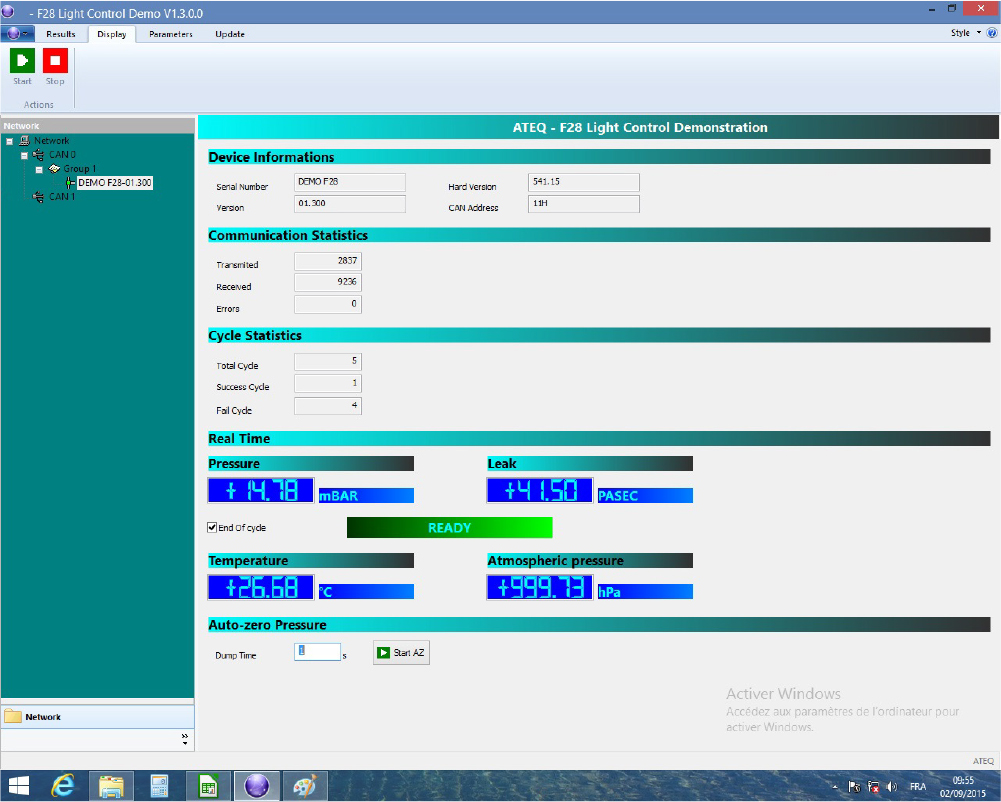

F28 LP Demo interface

F28 LP Demo interface

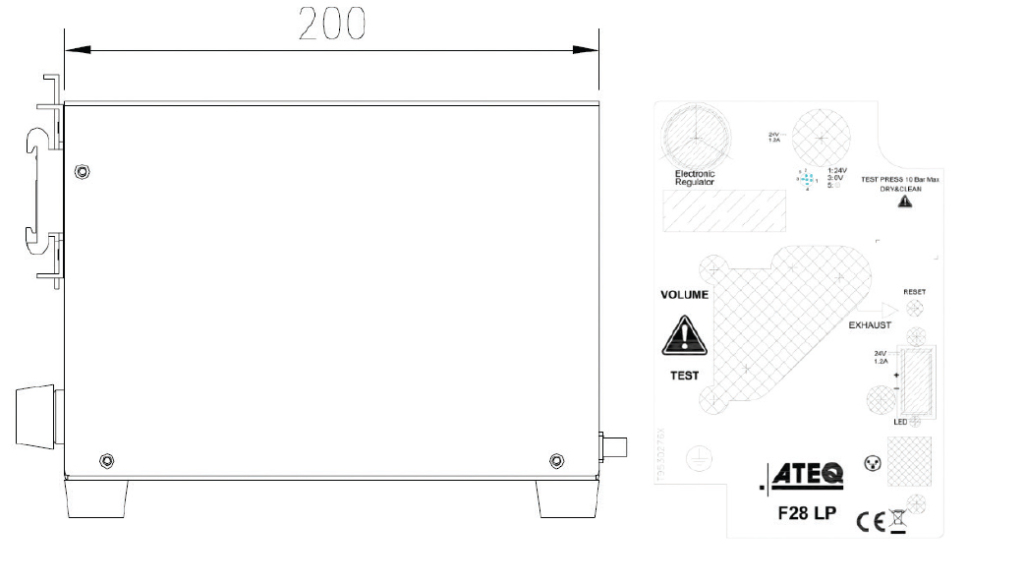

SPECIFICATIONS

- PHYSICAL

- Weight: 3.5 Kg

- Dimensions: (WxHxD) 225×141.5×97 mm

- ELECTRICAL SUPPLY

- Voltage: 24 V DC / 1.6 A

- TEMPERATURE

- Operating: + 5°C at + 45°C

- Storage: 0°C at + 60°C

- AIR SUPPLY

- Clean and dry air required

- Air quality standard to be aplied (ISO 8573-1)

- Test pressure input, need an external regulator

F28 LPV: TECHNOLOGY

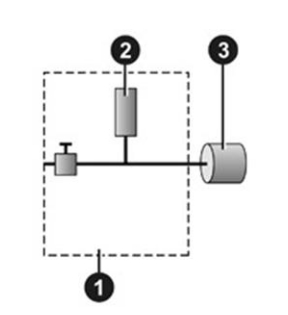

As a stripped down version of the previous technology, standard pressure decay compares the pressure on the part with the atmospheric pressure.

This technology is used when the application does not require a very high accuracy or a very fast cycle time. The method used is based on the measurement of a small variation or drop in pressure with a piezzo sensor.

Leak test and Desensitized Mode

The test pressure is applied to the input of the test part 3.

The measurement is performed by the pressure sensor 2.

1 Device

2 Pressure sensor

3 Part under test

TECHNOLOGY

DOCUMENTATION