SMART CHARGE 5

TRACER GAS CHARGING SYSTEM

The Smart Charge 5 is a fully automatic, custom configurable evacuation and tracer gas backfill system with built-in gross leak test. The system is ideally suited for pre-charging of product with tracer gas, such as Helium, Hydrogen or others prior to the leak test processes. It can also be used with any gas charging application that requires evacuation and subsequent pressurization of a test product.

SMARTCHARGE 5: PERFORMANCE

Base unit performs evacuation (25″ Hg), vacuum decay test and tracer gas backfill to 700 psig. Units can be configured to perform evacuation to lower vacuum levels.

SMART CHARGE 5: FEATURES

Main Features

- Recipes to include up to 10 leak locations, with user configurable dwell at each site

- Serial printer output

- Data logging over Ethernet

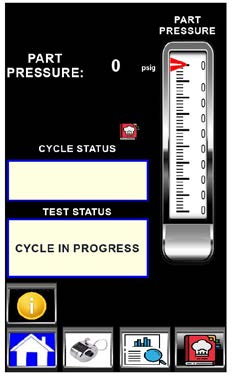

- Graphical user interface witch color touch screen

- 2 inputs; 2 outputs available for external use such as for fixture clamping, etc.

- Password protection prevents unauthorized access

- Built-in gross leak test eliminates tracer gas saturation

Standard Capabilities

- Maximum fill, pressures are up to 700 psig

- Ability to store up to 50-part recipes

- Touch screen 7″ color (HMI) for full system configuration/diagnostics display

- 16-bit analog input resolution on the pressure transducer

- System includes all necessary controls, gauging & valving

- 3CFM oilless product evacuation pump

- Allen Bradley MicroLogix 1400 PLC for all control, set-points

- Data storage and retrieval from front mounted USB port

SMART CHARGE 5: CHARACTERISTICS

Options

- Analog

- User I/O

- Printer

- Low pressure feature, 0-20 psig

- Nitrogen charge up 700 psig

- Barcode scanner feature

| TECHNICAL SPECIFICATIONS |

|---|

| Power | Universal Voltage 110 vac or 220-Volt AC, 50 – 60 Hz, 6.5 amps nominal |

|---|---|

| Dimensions (WxHxD) | 344 x 395 x 618 mm 13.5″ x 15.5″ x 24.4″ inches |

| Utility Fittings | 1⁄4” NPT female 1⁄2” NPT female for Part Evacuation |

| Pressure Transducer | Resolution of 0.01 psi in vacuum mode, or in pressure mode. Accuracy of ± 0.25%. |

| Valving | Fast acting pull type solenoid featuring epoxy encapsulated design |

| Manifolding | Seamless tubing with compression fitting interconnects. Helium leak tested to 1.0 × 10-6 atm-cc/sec@700 psig |

| Product Evacuation Pump | Air Driven Venturi Pump Providing ultimate vacuum level 25.5″ Hg |

| Electronics | Microprocessor-based programmable logic controller |

| Gauging | Digital part pressure and leak rate displayed on operator interface |