F600

LEAK TEST INSTRUMENT FOR INDUSTRIAL QUALITY CONTROL

With over 40 years of experience and 275,000 testers installed for more than 5,000 customers worldwide, ATEQ introduces its new entry level leak tester by absolute pressure measurement : F600.

New electronic module, new measurement module, new interface, new accessories… Everything has been designed to improve your quality control.

Yet, within it houses the latest leak testing techniques and technology, ensuring the fastest and most precise leak testing cycle available on the market.

F600: APPLICATIONS

AUTOMOTIVE

- Air Conditioning

- Radiators

- Exhaust

- Transmission…

PACKAGINGS

- Aerosol Caps

- Plastic Bags

- Sprays

- Plastic Bottles…

ELECTRONICS

- Hard Disk

- Watches

- TV Screen

- Camera Lenses…

F600: FEATURES

• Pressure decay leak measurement

• Mechanical or electronic regulator from vacuum to 20 bar

• 128 programs

• Setting on line (via USB)

• 2 languages (English + other one)

• Manual calibration on front panel with calibrated leak

• Data storage on internal memory or USB key

TEST MODES:

• Flow units (sccm, mm3/s, cm3/s, cm3/min, cm3/h…)

• Blockage test

• and others, depending on your applications

ENVIRONMENT:

ROHS standard

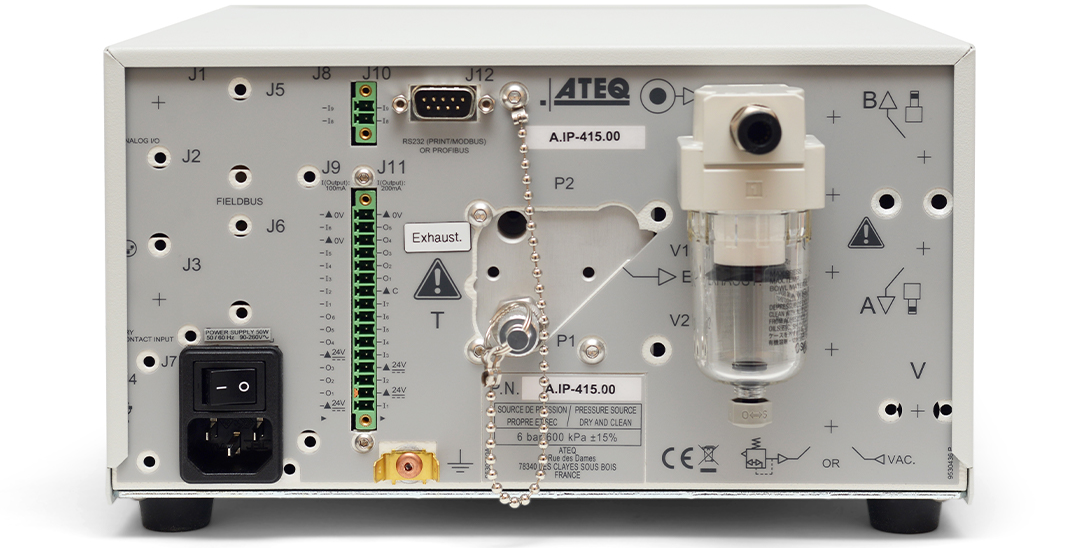

FLEXIBLE COMMUNICATION FORMAT:

• RS232: Printer, Modbus RTU

• Slave USB: PC supervision (WinAteq 300, sesame)

• Master USB: USB key to transfer (parameters, results, …)

• 6 inputs/ 6 outputs 24 V programmable for external automation

• Electronic regulator

MEASUREMENT CHARACTERISTICS :

| PRESSURE DROP MEASUREMENT |

|---|

| Test Range | Delta P Range | Accuracy* | Max. Resolution |

|---|---|---|---|

| Vacuum 500 Pa 5 Bar 20 Bar | 500 Pa (500 mbar) 1 kPa (Vacuum, 500 mbar, 5 bar, 20 bar) 5.00 kPa (Vacuum 500 mbar, 5 bar, 20 bar) 10.00 kPa (Vacuum, 500 mbar, 5 bar, 20 bar) 50.00 kPa (Vacuum, 500 mbar, 5 bar, 20 bar) 100.00 kPa (20 bar) | ± 1% Full Scale | 1 Pa (500 Pa) 0.01 kPa (other) |

F600: SPECIFICATIONS

- PHYSICAL

- Weight: 7 Kg

- Dimensions: (WxHxD) 255x150x270 mm

- ELECTRICAL SUPPLY

- 24VDC/2A

- TEMPERATURE

- Operating: + 5°C at + 45°C

- Storage: 0°C at + 60°C

INTERFACE

- Graphic color screen with simple and intuitive menu-driven operator controls

- SMART KEY: programmable key with user’s functions

- AIR SUPPLY

- Command 4/6 bar

- Pressure 1 or 2 bar > test pressure

- Clean and dry air

- Air quality standard to be applied (ISO 8573-1)

- Command 4/6 bar

F600: OPTIONS

• 2 pneumatic outputs for control of sealing connectors

• Small volume (F600 LP)

• Small volume/ vacuum (F600 LPV)

F600: TECHNOLOGY

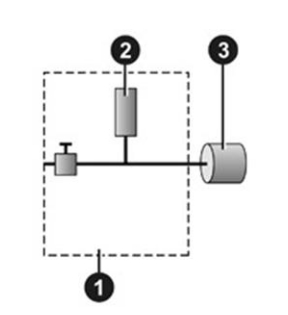

As a stripped down version of the previous technology, standard pressure decay compares the pressure on the part with the atmospheric pressure.

This technology is used when the application does not require a very high accuracy or a very fast cycle time. The method used is based on the measurement of a small variation or drop in pressure with a piezzo sensor.

Leak test and Desensitized Mode

The test pressure is applied to the input of the test part 3.

The measurement is performed by the pressure sensor 2.

1 Device

2 Pressure sensor

3 Part under test