What is IP Rating?

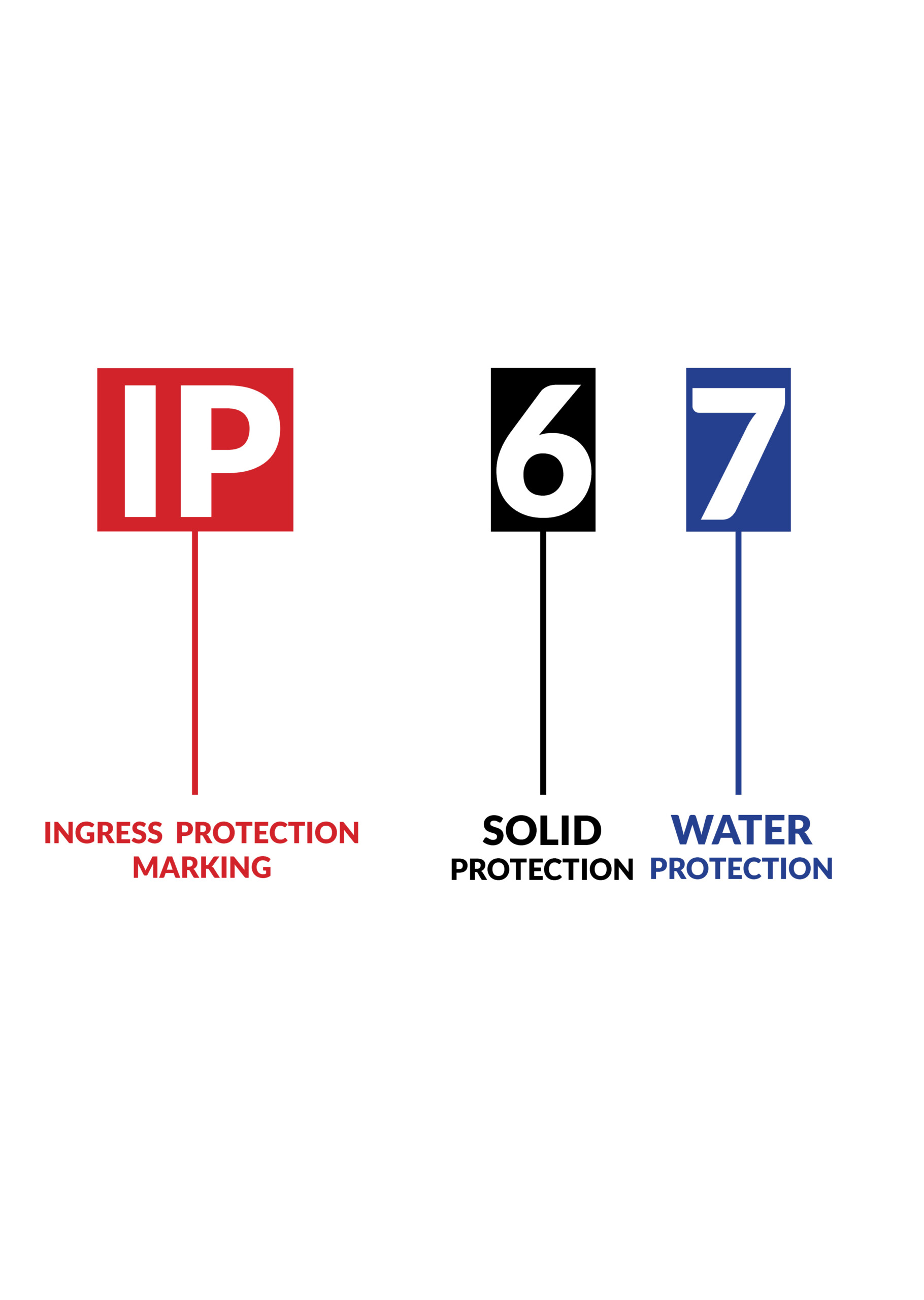

IP Rating, or Ingress Protection Rating, is a universal standard set by the International Electrotechnical Commission (IEC). This standard is designed to provide consumers and manufacturers with a clear understanding of how well a device is protected against external elements like dust, water, and even mechanical intrusions. The IP Rating is usually expressed as a two-digit code, where each digit represents a specific level of protection.

The first digit in the IP code indicates the level of protection against solid particles, such as dust. The scale ranges from 0, which means no protection, to 6, which signifies complete protection against dust ingress. The second digit represents the device’s resistance to liquids, particularly water, and ranges from 0 (no protection) to 8 (protection against prolonged submersion).

What is the Difference between IP67 and IP68?

In an IP67 rating, the ‘6’ signifies that the device is completely dust-tight, offering full protection against dust and particulate matter. The ‘7’ indicates that the device can be temporarily submerged in water up to 1 meter deep for a duration of 30 minutes without sustaining any damage. This makes IP67-rated devices ideal for outdoor activities and environments where they may be exposed to rain, splashes, or brief accidental submersion.

An IP68 rating takes water resistance a step further. While it also offers complete dust protection, indicated by the ‘6’, the ‘8’ in IP68 means the device can be submerged in water deeper than 1 meter for extended periods. The exact depth and duration are generally specified by the manufacturer. This makes IP68-rated devices suitable for more extreme conditions, such as underwater photography or activities that involve prolonged exposure to water.

Understanding the nuances between IP67 and IP68 can help consumers make informed decisions based on their specific needs, whether it’s for everyday use, outdoor adventures, or specialized activities like diving or industrial work.

By delving into what IP ratings like IP67 and IP68 actually signify, both manufacturers and consumers can better assess the level of protection a device offers, ensuring that it meets the demands of its intended use.

How Does IP67 Waterproof Testing Work?

The IP67 testing process begins with a thorough examination of the device’s design, materials, and assembly. This helps in determining the appropriate leak rate based on the targeted IP rating. Automated, dry, non-destructive leak tests are generally recommended for better accuracy and repeatability. These tests are crucial for manufacturers to ensure that their devices, such as smartphones, smartwatches, and fitness trackers, meet the IP67 standards.

What is the Process for Sealed Device Leak Testing?

To achieve an IP67 rating, the device must resist dust and withstand submersion in up to 40 inches of water for half an hour. Traditional pressure or vacuum decay tests are not suitable for sealed devices. Instead, a volumetric fill test process is often used. The device is placed in a sealed chamber, and the air or space around it is tested for leaks. This ensures that there are no gross leaks in the device before proceeding to the fine decay leak test.

What are the Benefits of IP67 Waterproof Testing?

Conducting IP67 tests with reliable instruments ensures regulatory compliance and customer satisfaction. It also reduces the risk of recalls or expensive repairs. Moreover, high-quality testing instruments offer fast test cycles, allowing manufacturers to produce more devices in less time.

How Do You Choose the Right Test Method for IP67 Waterproof Testing?

Choosing the right test method depends on various factors like part characteristics, leak paths, and risk of failure. The most commonly used methods include Pressure Decay, Differential Pressure Decay, and Tracer Gas Sniff/Accumulation.

Consult with our experienced leak test engineers to select the most suitable method for your specific application.

| Benefits of IP76 Water Proof Leak Testing with ATEQ |

|---|

| Regulatory Compliance:

ATEQ customers benefit from accurate, reliable test results that ensure that their manufactured devices pass and meet all compliance standards. |

| Fast:

ATEQ instruments have the fastest test cycles on the market. Faster test cycles reduce the time it takes to test each device, allowing manufacturers to produce more products in less time. |

| Reliable:

ATEQ instruments and systems use proprietary technology and in-house sensors that ensure accurate test results that are repeatable every time. This benefits the manufacturer because they know that the parts that pass, are safe, reliable, and meet industry standards. |

| Risk Reduction:

Manufacturers benefit from a reduced risk of having parts, devices, or components recalled or having to pay for expensive repairs when working with an ATEQ leak tester. |

| Customer Satisfaction:

ATEQ leak testers help manufacturers produce high-quality products that meet customer expectations. |