When leak testing a large, flexible component in a ‘noisy’ factory environment, use ATEQ’s new Differential Noise Canceling (DNC) leak testing technology to produce faster, more accurate leak readings that are not influenced by fluctuating background disturbances. A factory is “noisy” and full of fluctuations which can affect a leak reading and cause the leak tester to incorrectly pass or fail a part.

Factory Disturbances

Temperature Variations: Opening Doors or Windows, Fans, HVAC Systems

Pressure Variations: Time of Day, Weather, Sound Level

Vibrations: Machine Movement, Wind, Forklifts, Music

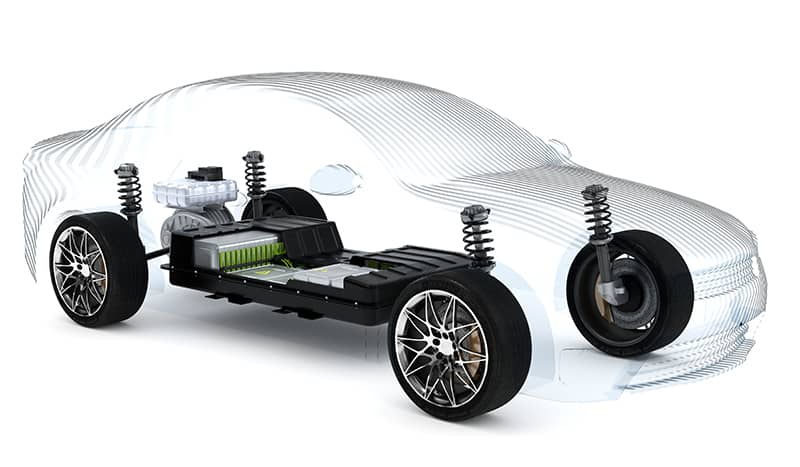

An EV battery housing is a great application for ATEQ’s new DNC leak testing technology since it is a large, flexible component that is easily affected by variations in background noise.

ATEQ’s DNC function provides a more stable leak reading by compensating for background disturbances so they don’t influence the leak sensor.

By using ATEQ’s F620 Large Volume Differential Pressure Decay Leak Tester with DNC, it is now possible to detect pressure drops below 0.1Pa/s.

Leave A Comment

You must be logged in to post a comment.